Phoenix Auto Glass Science

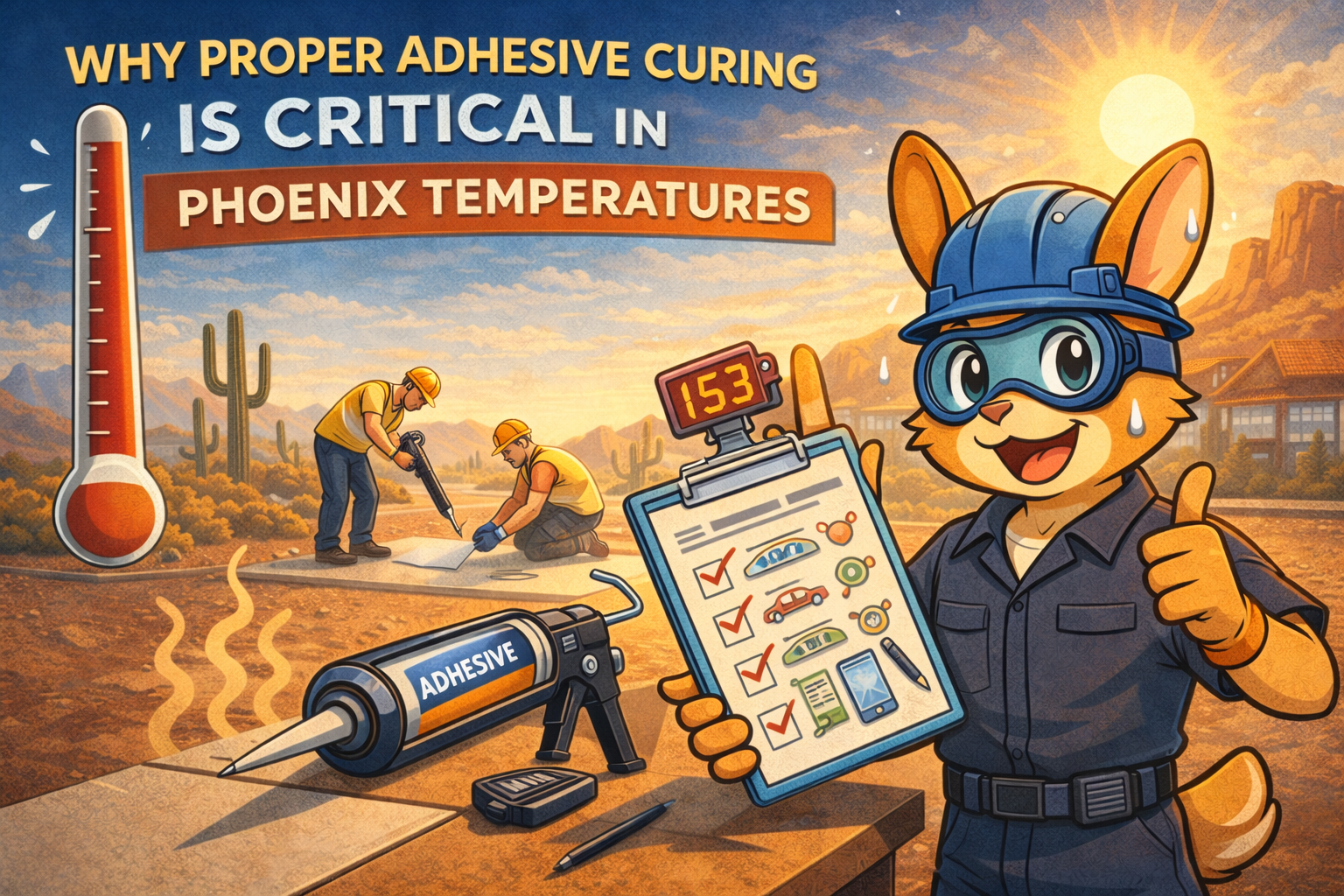

Why Proper Adhesive Curing Is Critical in Phoenix Temperatures

Phoenix heat does not just affect comfort, it directly changes how automotive urethane adhesives behave. High temperatures speed chemical reactions, shorten working time, and can weaken long term bond strength if conditions are not controlled. At Rabbit Auto Glass of Phoenix, adhesive curing is one of the most important factors in windshield replacement quality. Below, we explain what happens during curing in Phoenix, how we adapt our process, and why shortcuts create real safety risks.

How Phoenix Heat Changes Adhesive Curing Behavior

Windshield adhesives cure through chemical reactions that are strongly influenced by temperature. In Phoenix, ambient air and glass surface temperatures regularly exceed the conditions used in manufacturer testing.

Higher heat speeds polymerization and moisture driven reactions, which reduces open working time and increases the risk of uneven bonding. If adhesive skins over too quickly, it may not fully bond to the glass or vehicle frame, reducing crash retention strength.

Local reporting from AZ Central has shown that vehicle surface temperatures in Phoenix can exceed one hundred sixty degrees during peak sun exposure. AZ Central Phoenix heat coverage

Which Windshield Adhesives Perform Best in Extreme Heat

Not all automotive urethane adhesives perform the same in high temperature environments. Products designed for desert climates maintain elasticity and strength while still curing within safe drive away times.

In Phoenix, we rely on manufacturer approved adhesives with higher thermal tolerance and stable crosslink structures. These properties help the bond resist softening, shrinkage, and degradation caused by constant heat cycling.

Temperature Control Strategies Used During Installation

Proper curing in Phoenix requires active temperature management, not guesswork. We monitor air temperature, glass temperature, and vehicle interior conditions before and during installation.

Shade, insulation, and controlled staging reduce temperature spikes that cause uneven curing. Substrates are conditioned to remain within adhesive specifications before application begins.

Phoenix area news outlet 12 News has reported how extreme summer heat affects vehicle materials and safety systems. 12 News reporting on Phoenix heat and vehicles

Why Checklists Matter for Consistent Results

We use structured curing checklists to reduce variability between installations. These track surface preparation, adhesive batch data, temperature readings, and cure timing.

In Phoenix conditions, even small deviations can affect durability. Documentation allows us to verify compliance and maintain consistent results year round.

Preventing Failures and Maximizing Performance Over Time

Most adhesive failures trace back to rushed cure times, improper surface preparation, or ignored temperature limits. Phoenix heat amplifies all of these risks.

When issues arise, we evaluate moisture exposure, substrate condition, and cure timing against manufacturer guidance. Long lasting performance depends on selecting the right materials and respecting cure requirements.

Frequently Asked Questions

Yes. High temperatures accelerate curing and can weaken bond integrity if conditions are not controlled.

Yes. If adhesive cures too quickly, it may not properly bond to the glass and vehicle structure.

Many manufacturers offer formulations better suited for high heat regions. Using the correct product is essential for safety and durability.

We verify cure timing, temperature data, and safe drive away guidelines before releasing the vehicle.