Auto Glass Engineering Explained

The Science Behind Windshield Chip Repair

At Rabbit Auto Glass of Phoenix and Tucson, windshield chip repair is not guesswork. It is applied materials science, structural physics, and controlled chemistry. Modern windshields are laminated safety systems, not simple glass panels. When a chip forms, our goal is to stabilize the structure, restore load transfer, and preserve safe visibility. Below, we explain how windshield glass is built, how chips behave, and why proper repair techniques matter in Arizona conditions.

How Windshields Are Engineered and Why Repairs Are Possible

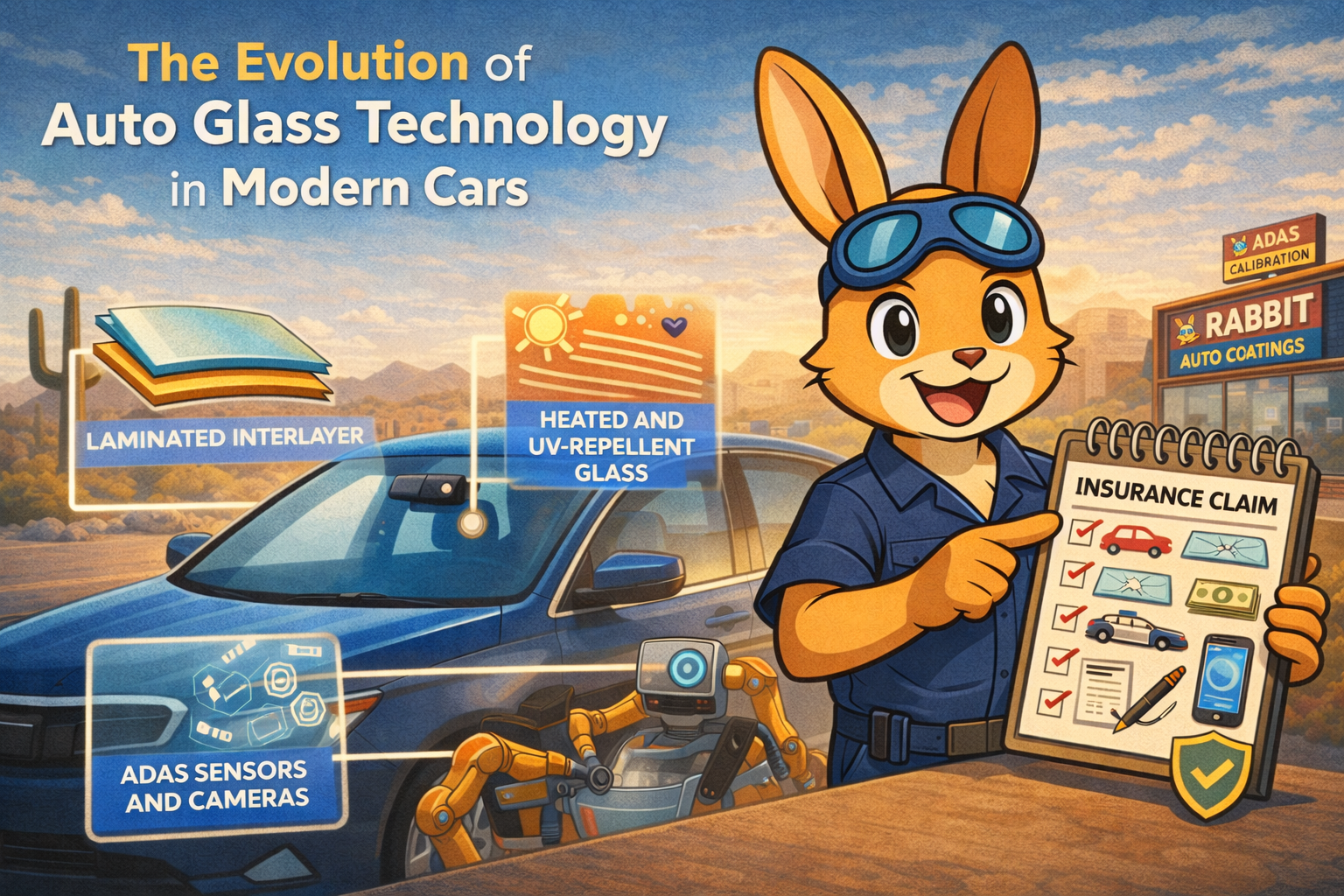

Modern windshields are constructed from laminated safety glass, consisting of two glass layers bonded to a polyvinyl butyral interlayer. This interlayer absorbs energy and prevents shattering during impact, which is why windshields crack instead of exploding.

According to guidance from the National Highway Traffic Safety Administration, the windshield contributes to roof strength and supports airbag deployment. Because the glass layers remain bonded after damage, small chips can often be stabilized without full replacement.

Understanding this laminated structure explains why repairs focus on filling cracks rather than simply hiding damage.

Source, National Highway Traffic Safety Administration vehicle glazing overview

What Happens When a Windshield Chip Forms

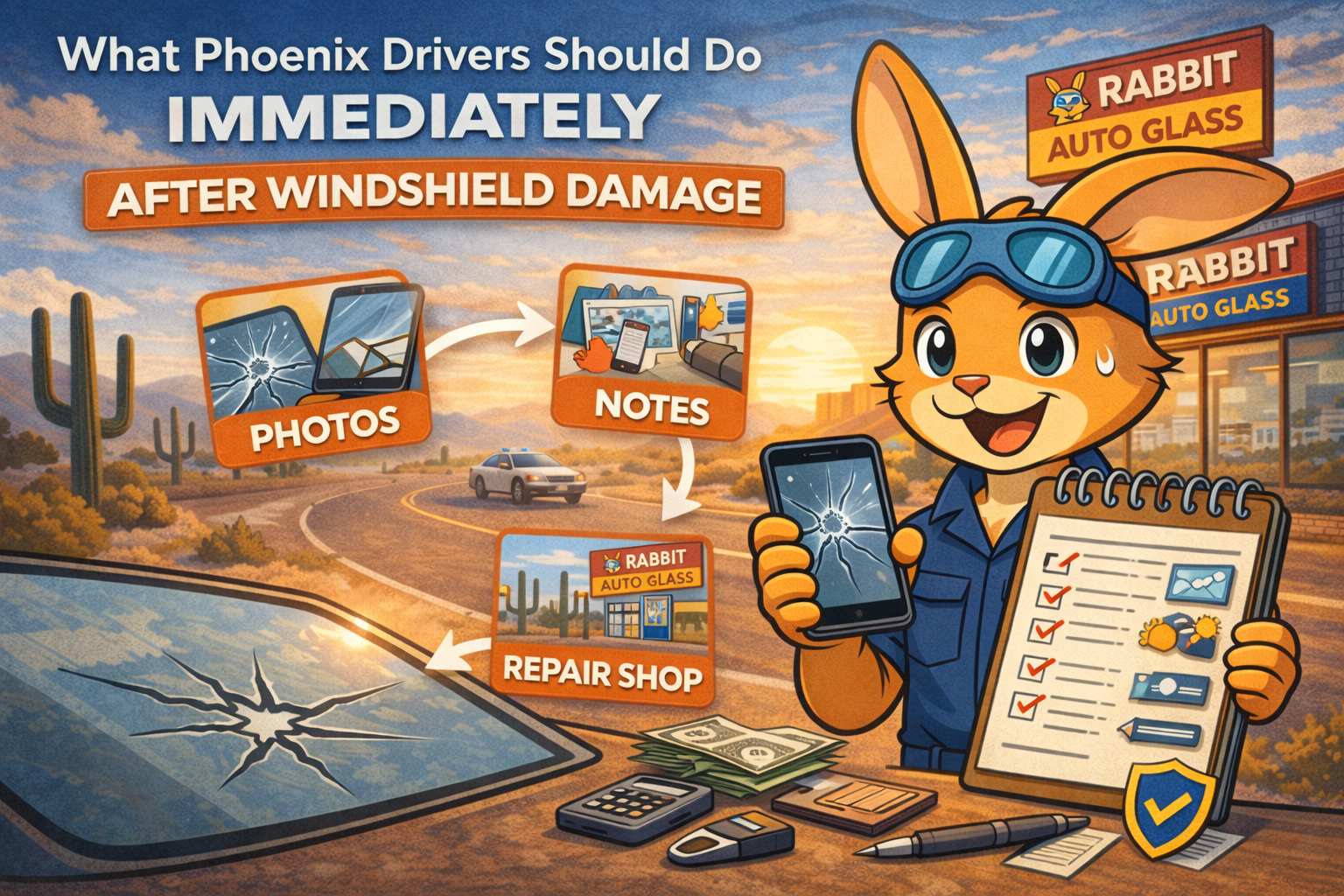

A chip begins with a high energy impact, usually from road debris. The impact creates a localized stress concentration that radiates outward through the glass layers.

Microcracks form at the impact point and branch depending on glass thickness, angle of impact, and temperature. In Arizona, temperature plays a major role, as rapid heating and cooling increase internal stress.

Arizona Department of Transportation safety reporting highlights how roadway debris contributes to windshield damage across the state. Early inspection matters because microcracks grow faster under thermal cycling.

Source, Arizona Department of Transportation road safety information

How Resin Injection Restores Structural Integrity

Windshield chip repair works by injecting a specialized resin into the microcrack network. This resin is engineered to flow under pressure, bond to glass surfaces, and cure into a rigid, transparent polymer.

When properly injected, the resin restores load paths that were disrupted by the impact. It also blocks moisture and contaminants that accelerate crack growth.

Optical performance depends on matching the resin refractive index closely to the surrounding glass. This is why professional repair improves clarity but may not return the glass to factory appearance.

Timing, Pressure, and Curing in Real World Conditions

Resin behavior is highly sensitive to timing, pressure, and temperature. Injection must occur while viscosity allows full penetration into microcracks.

Pressure drives resin into narrow fracture paths, but excessive pressure risks extending cracks. Controlled curing ensures the polymer hardens evenly without trapping air.

In Arizona heat, cure timing is closely monitored to avoid premature hardening. This process aligns with best practices referenced by Consumer Reports when discussing windshield repairs and safety.

Source, Consumer Reports on windshield repair and replacement safety

Choosing Repair or Replacement Based on Science

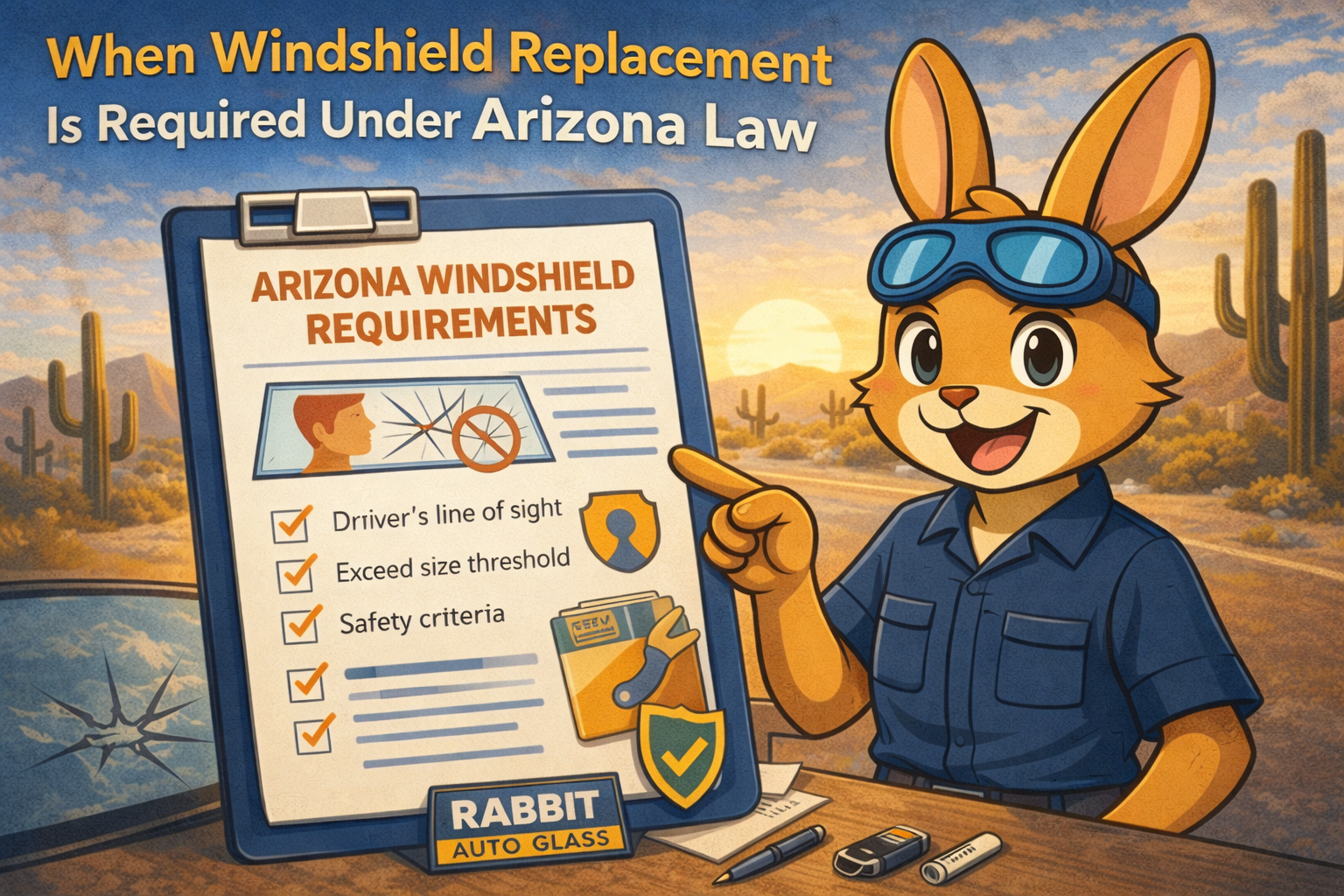

Not every chip is repairable. We evaluate crack length, depth, edge proximity, and optical impact before recommending repair.

Chips near edges or within critical viewing areas often experience higher stress and reduced repair longevity. In those cases, replacement is the safer choice.

Our recommendations are based on structural integrity and safety standards, not convenience. This ensures long term performance under Arizona driving conditions.

Frequently Asked Questions

A repair restores structural continuity but does not return the glass to factory condition. It stabilizes damage and improves safety when performed correctly.

Yes. Heat accelerates aging and stress, which is why material choice and curing control matter in Arizona.

Edge chips experience higher stress and often require replacement instead of repair.

Yes. Moisture interferes with resin bonding and must be removed before injection.