Phoenix Auto Glass Guide

Environmental Benefits of Windshield Repair Over Replacement

At Rabbit Auto Glass of Phoenix, we help drivers choose the safest option first, and when a repair is safe, it is often the greener option too. Repairing a chip usually uses far fewer materials than replacing the entire windshield, which can reduce waste, transportation, and the energy tied to manufacturing a new glass panel. Replacement is sometimes required for safety, but when a repair qualifies, it can be a practical way to reduce environmental impact while getting you back on the road faster. Stick with us and you’ll see what drives the footprint difference, plus simple ways to make your glass service even greener.

Why Repairing Saves More Than You Think

When a windshield chip can be repaired safely, the environmental upside is straightforward, you keep the original glass in place and avoid the footprint of producing, shipping, and installing a full replacement windshield. A repair typically uses a small amount of resin and minimal consumables, while replacement requires a new laminated glass panel, adhesives, and often additional parts like moldings.

Repairs can also cut downtime, which can reduce extra trips and logistical steps. The most important point is scope, repair addresses a localized defect, replacement replaces an entire assembly.

We also keep the message realistic, repairs do not make the windshield brand new, and not every chip should be repaired. When the damage meets repair criteria, repair can be the lower waste option without compromising safety.

The Environmental Footprint of Windshield Replacement Explained

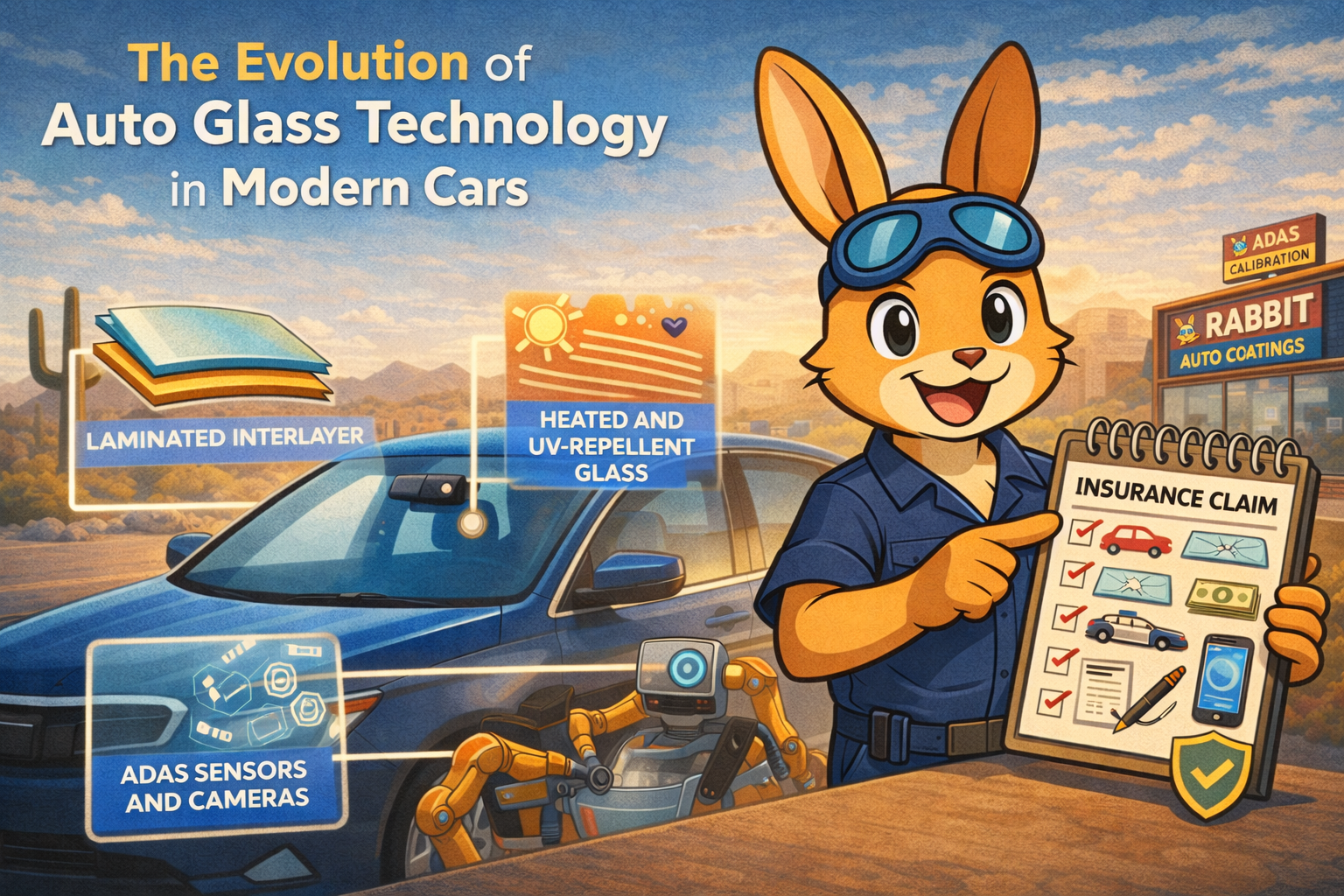

Windshield replacement is sometimes unavoidable, but it usually has a larger footprint because it involves manufacturing a new laminated glass panel and transporting it through a supply chain. Glass production is energy intensive, and laminated windshields include an interlayer that can complicate recycling at end of life.

Transportation adds impact too, especially when glass is sourced from farther away or routed through multiple distribution steps. Installation materials, like urethane adhesives, primers, and packaging, also add to the total material use compared with a small resin repair.

The takeaway is not to avoid replacement when it is required, it is to recognize that replacement is a larger intervention. When repair is safe and appropriate, it usually avoids much of that upstream footprint.

How Repair Preserves Laminated Glass and Reduces Waste

Most windshields are laminated, which means two layers of glass with a plastic interlayer between them. A chip repair works by cleaning the break and filling it with resin to stabilize the damaged area and improve clarity.

When done early and the damage qualifies, repair can slow or stop a chip from turning into a crack, which can prevent a full replacement. That matters for waste reduction, keeping the original laminated glass in place means fewer panels being scrapped and fewer materials needing disposal or specialized recycling.

We also set expectations, repairs can improve strength and appearance, but they are not invisible, and they are not appropriate for every type of damage. If a repair cannot meet safety and visibility standards, replacement is the right call.

Resource Savings: Energy, Materials, and Transportation

The biggest resource savings usually come from avoiding new glass production and long distance shipping. Repair uses fewer raw materials, fewer packaging materials, and typically fewer transported parts than a replacement.

There are also practical transport benefits. A repair often can be completed quickly, sometimes same day, which can reduce extra driving, towing, or repeated shop visits. Mobile service can reduce trips further when scheduling and conditions allow.

If you want the greenest outcome, the best lever is early action. Fixing a chip early can keep it repairable, which keeps the work smaller in both cost and environmental impact.

Real World Impact and Practical Tips for Greener Repairs

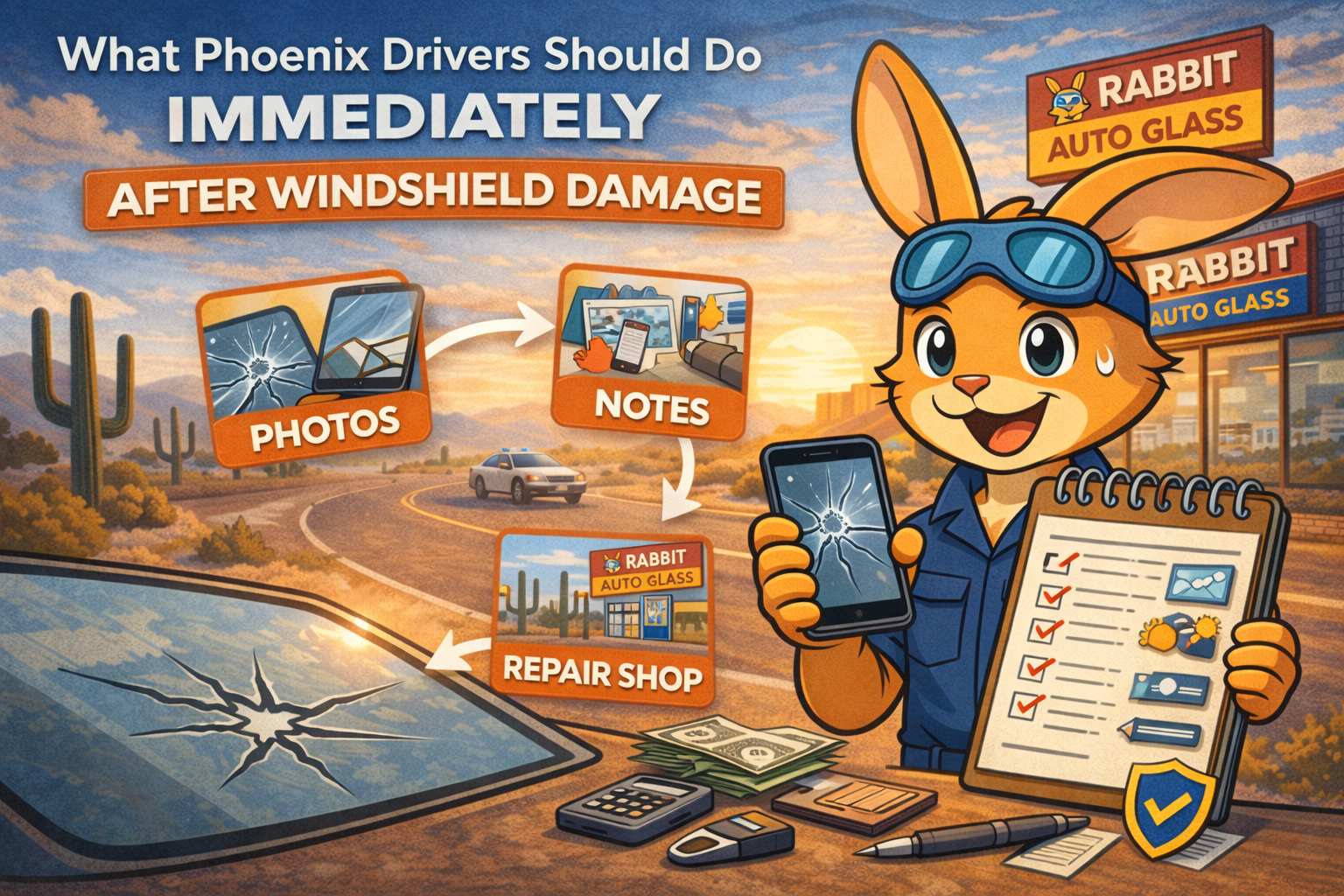

Greener auto glass service is mostly about smart decisions and clean execution, repair when it is safe, replace when it is required, and avoid delays that let small damage spread. Here are practical ways to reduce impact without compromising safety.

Tip one; address chips quickly, heat, vibration, and road shock can turn a small chip into a long crack. Tip two; ask about mobile repair when appropriate, one trip can be avoided if conditions and the job support it. Tip three; choose a shop that keeps materials controlled and waste managed, including proper handling of packaging and consumables.

If replacement is required, ask about glass quality, proper installation steps, and calibration needs when applicable, doing it right the first time avoids rework and additional waste. At Rabbit Auto Glass of Phoenix, we focus on safe outcomes, clear communication, and efficient service that fits real world driving in Arizona.

Frequently Asked Questions

Repair can reduce local emissions indirectly by avoiding the manufacturing and freight steps tied to a full replacement windshield. It can also reduce extra trips when the repair is quick or mobile service is used. The biggest air quality benefits come from preventing replacement when a safe repair is possible.

Yes, reputable shops follow established industry repair standards and manufacturer guidance. The repair must restore safe visibility and stabilize the damage, and some damage locations or sizes should not be repaired. If a repair cannot meet safety criteria, we recommend replacement.

Repair does not directly change the windshield bonding urethane because the windshield stays installed. In that sense, repair avoids disturbing the original bond and trims that would be removed during replacement. If replacement is required, a proper install is what protects sealing performance long term.

Yes, professional repairs use purpose built tools and resins designed for windshield damage, along with controlled cleaning and curing steps. The material footprint is usually small compared with replacement, but technique matters for strength and clarity.

Look for shops that follow recognized auto glass safety and installation standards, use trained technicians, and provide written workmanship warranties. If you have advanced driver assistance features, ask about calibration capability and documentation.